The RETRO PILOT

"Retropilot" is a one-man band, and the lead singer is James: an ex-Royal Australian Air Force pilot who now works full time as a certified sticker magician.

After graduating from the Australian Defence Force Academy in 2012 (studying Science), James began his RAAF pilot training on the CT-4B. Over the next few years, his training would see him progress through the PC-9, Hawk-127 and the F/A-18F. Whilst on the Super Hornet conversion course, James actively demonstrated his suitability for flying something significantly slower. After a few turbulent months he transferred across to 36SQN where he became a Captain on the C-17A Globemaster.

James has about 2000 hours on the C-17 and has flown all over the world. His career highlights included operations in the Middle East, multiple missions to Antarctica, and a 10 day 'break' in Oxford (UK) with a wonderfully persistent hydraulic issue.

While James always enjoyed flying, it never quite scratched his creative itch. Retropilot provided a welcome change from the highly structured and regulated airborne environment. He is a completely self taught graphics designer, and has sharpened his skills over the better part of a decade.

"Retropilot" is not a cult, but the enthusiasm that customers have for their purchases may convince you otherwise.

Keep scrolling to find out why Retropilot products are some of the best in the business.

THE PROCESS

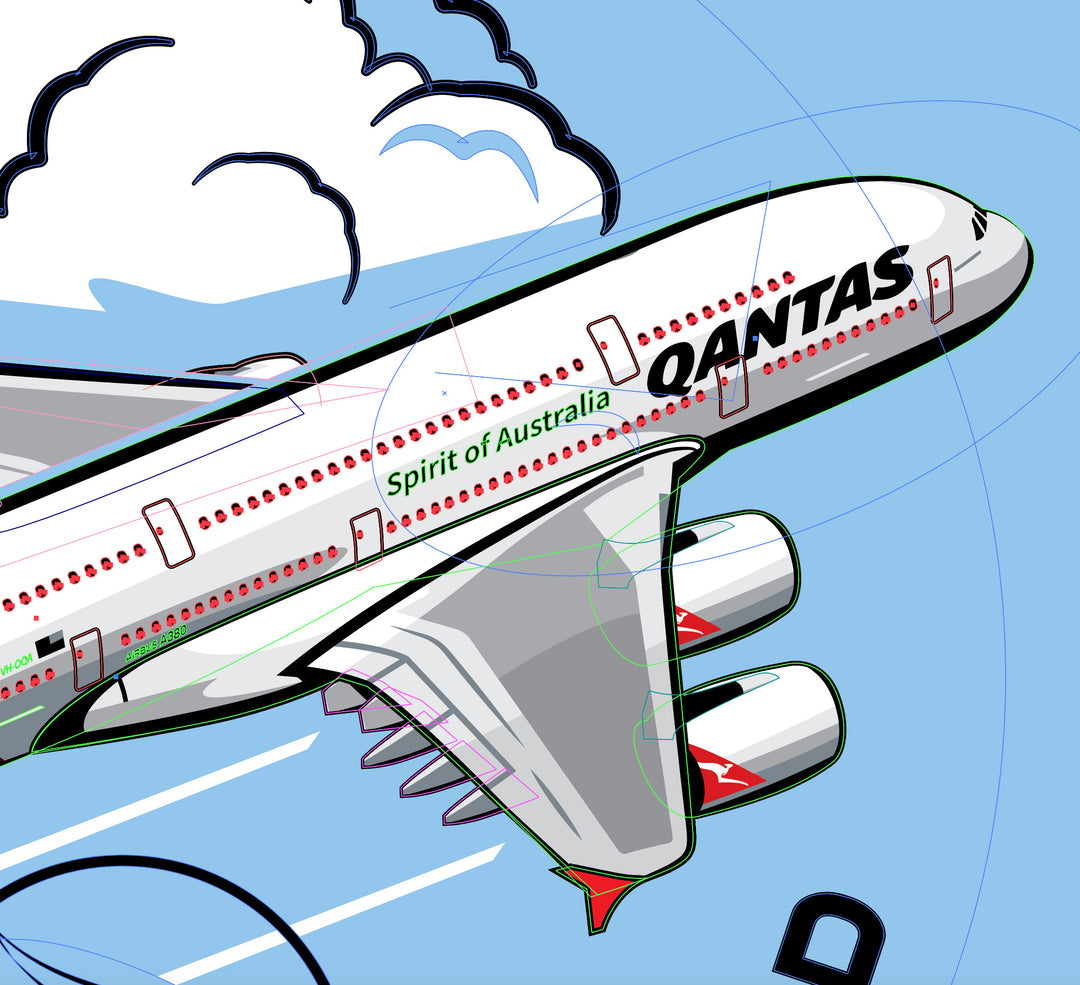

All Retropilot designs are created in Adobe Illustrator. The process begins by finding a reference image that displays the aircraft in a way that works with the proposed text and sticker shape.

James then gets to work by "tracing" the subject by hand and breaking the aircraft up into areas of shadows and highlights. The goal is to simplify the aircraft so that it no longer looks like a photograph.

The challenge is to strike a balance between too simple and too detailed. This process usually takes 1-2 hours of intense concentration and swearing.

See below for an example of the simplification process.

PRINTED THE HARD WAY

Once the design stage is completed, Retropilot designs are sent to California to be printed using an old-school method called Screen-Printing.

Screen-printing is a time-consuming art form that requires a meticulous approach to detail and quality. You can't simply press "Print" on a computer, as many of the steps of the screen-print process are still done by hand!

All up, it takes about three weeks to print a new batch of Retropilot stickers.

Hardly anyone prints this way anymore because of the extra set-up costs and time involved, but the end result is absolutely worth the extra effort.

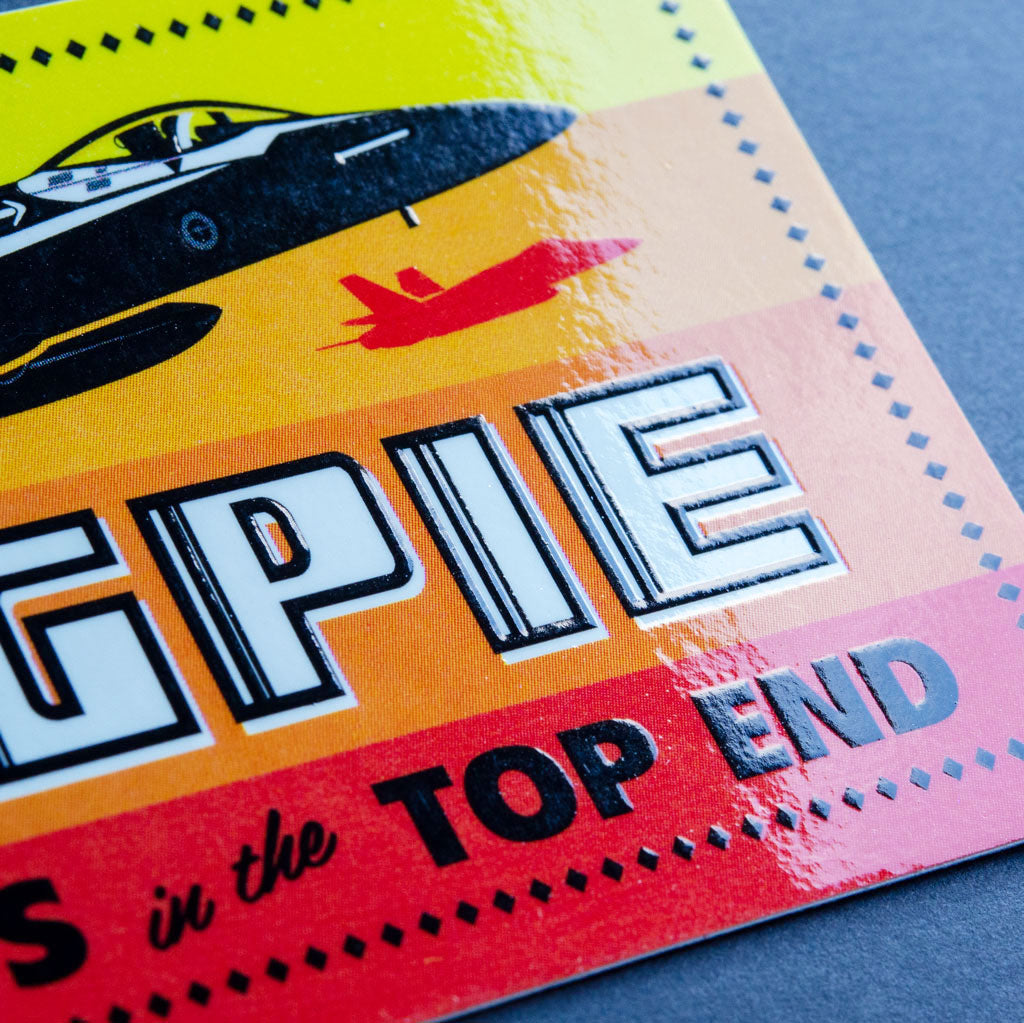

VIBRANT AF

Thanks to the screen-printing process, Retropilot stickers have some of the brightest and most vibrant colours you'll ever see on a sticker.

This occurs because screen-printed ink is, on average, 700% thicker than what you'd find on 'regular' stickers that come out of an inkjet printer.

Thicker ink results in incredibly eye-catching colours that really make the designs pop.

THICKNESS MATTERS

The ink is so thick that you can literally see it raised off the sticker surface. The darker the colour, the more the ink will be raised.

For a truly sensual sticker experience, run your finger over the design and feel the undulations of each colour change.

In this close up picture of an F-111 sticker, you can see how the black ink is noticeably raised above the rest of the colours.

The textured finish is a truly spectacular feature of screen-printing, and one that you will quickly fall in love with.

BACK IT UP

It's all party in the back over here at Retropilot.

Each sticker has a beautiful back-print design (in black and white) to ensure you get double the artwork! The batch printing date is also annotated for your records.

LONG LASTING PERFORMANCE

Screen-printed stickers are your best option if you prefer a higher calibre, higher quality, and longer lasting sticker. All stickers in the Retropilot store are rated for indoor and outdoor use.

When applied properly to a smooth, dry and clean surface, they will easily tolerate brutal ocean waters, harsh desert sun or freezing Arctic winters.

If you choose to put them on an indoor surface (e.g. a laptop or toolbox), they will likely be uncovered by the archeologists of the future.